Introduction

In today’s competitive industrial landscape, energy efficiency is no longer an option—it is a necessity. Rising fuel prices, climate change regulations, and the growing demand for sustainable operations push companies to adopt smarter solutions. BROAD Indonesia, a leader in energy-saving cooling and heating systems, delivers turnkey solutions that reduce operational costs, cut carbon emissions, and extend equipment lifespan.

A recent case study at Aalst Chocolate, Singapore demonstrates how BROAD’s innovative technology transformed an energy-intensive chocolate production facility into a model of efficiency and sustainability. Similar solutions are now available for Indonesian industries such as food & beverage, pharmaceuticals, chemicals, textiles, and data centers.

Project Background: The Challenge of Rising Energy Costs

Aalst Chocolate, a world-class manufacturer exporting to more than 50 countries, faced increasing operational costs due to high natural gas prices. Its cooling and heating systems, essential for chocolate production and storage, consumed excessive energy.

To maintain efficiency, Aalst turned to BROAD for a complete energy-saving renovation. The challenge was clear: reduce energy costs while ensuring stable, 24/7 operations for sensitive food processing.

BROAD’s Turnkey Solution

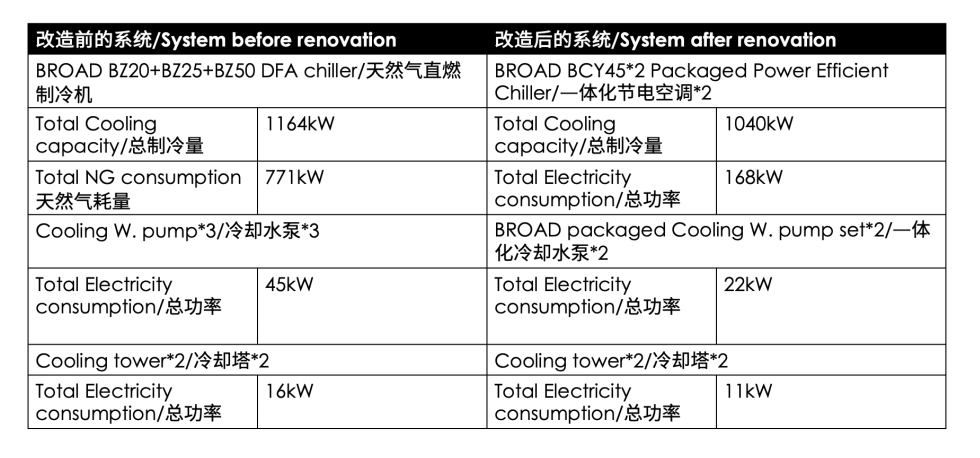

BROAD Indonesia provides customized renovation and energy retrofit projects with advanced equipment and smart engineering. In the Aalst Chocolate project, the outdated natural gas chillers were replaced with packaged magnetic bearing power-efficient chillers and direct fired heaters, supported by optimized pipelines and power distribution systems.

Key benefits of BROAD’s packaged system include:

- High energy efficiency with magnetic bearing compressors.

- Low maintenance due to innovative design (no gear belts, reduced wear).

- Plug-and-play installation, minimizing factory downtime.

- Turnkey delivery, covering system design, equipment supply, installation, and commissioning.

The project was completed in just 10 days—with significant cost savings and uninterrupted production afterward.

Measurable Results: Efficiency & Sustainability

After renovation, Aalst Chocolate achieved:

- Over USD 20,000 monthly energy savings with a payback period of only 4 years.

- 541 tons of CO₂ reduction per year, equivalent to planting 30,000 trees.

- Stable 24/7 operation with full system redundancy.

- Less maintenance costs through advanced compressor and cooling tower design.

- Real-time monitoring with smart energy management software.

Why BROAD Indonesia?

Indonesia’s industries face similar challenges: high energy prices, growing sustainability demands, and the need for reliable cooling & heating systems. BROAD Indonesia offers:

✅ Customized solutions for factories, malls, data centers, and hospitals.

✅ Proven track record with global leaders like Cargill, Aalst, and Fortune 500 companies.

✅ Green technology aligned with Indonesia’s energy transition goals.

✅ Fast installation & turnkey services to minimize downtime.

Conclusion

BROAD Indonesia helps companies reduce energy costs, improve sustainability, and enhance competitiveness. Just like Aalst Chocolate in Singapore, Indonesian businesses can now transform their operations with smart energy-saving renovations.

👉 Contact BROAD Indonesia today to explore how we can help your business save energy, cut emissions, and lead the way toward a greener future.