Transforming Waste into Clean Energy with BROAD Absorption Chillers

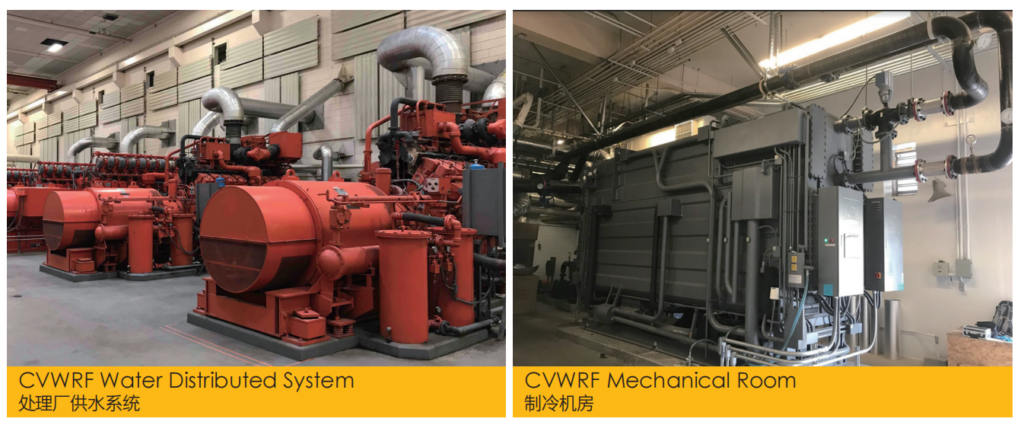

The Central Valley Water Reclamation Facility (CVWRF) in Salt Lake City, Utah, is one of the most advanced wastewater treatment plants in the United States. With a capacity of 75 million gallons of water treated daily, it ensures clean water returns to the Jordan River system while also turning waste into a valuable source of energy.

In 2018, CVWRF upgraded its over 30-year-old Combined Cooling, Heat and Power (CCHP) system, making it a model for sustainable energy practices in wastewater treatment. At the heart of this system is the BROAD single-stage absorption chiller, which utilizes recovered heat from biogas engines to provide efficient cooling for the facility.

How the System Works

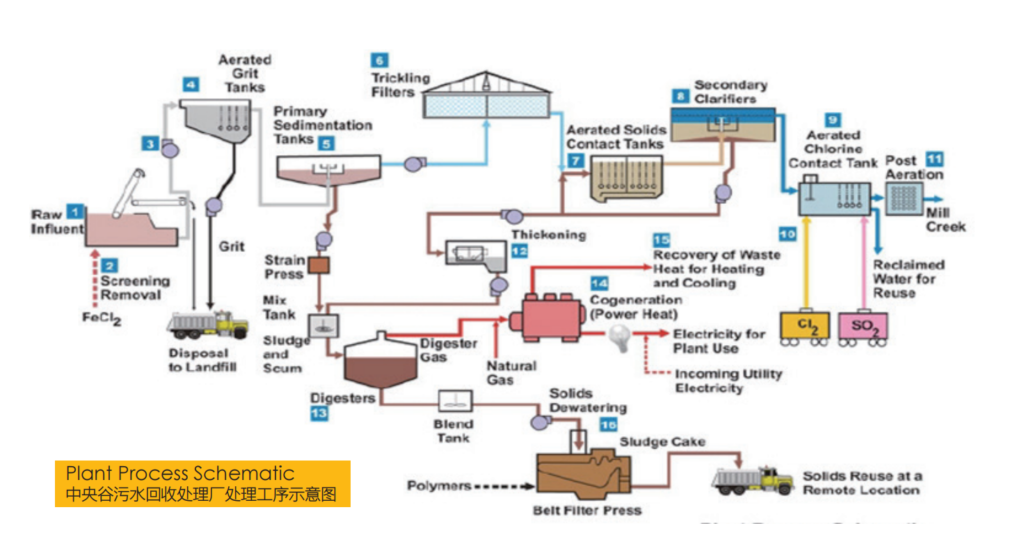

- Biogas Utilization: Wastewater sludge is digested to produce biogas, which fuels reciprocating engines for electricity generation.

- Heat Recovery: The recovered heat is captured through a thermal system and used for sludge heating, building heating, and driving BROAD absorption chillers.

- Efficient Cooling: The BROAD absorption chiller provides 400 RT of cooling capacity, eliminating the need for conventional cooling towers and saving over 17 million gallons of city water annually.

This integration of power, heat, and cooling ensures that over 85% of the facility’s electricity demand is met internally, reducing reliance on external energy sources.

Project Value and Environmental Benefits

The BROAD absorption chiller at CVWRF offers unique advantages for wastewater treatment plants:

- Energy Efficiency: Boosts overall system efficiency to above 80%, compared to less than 55% for traditional plants.

- Cost Savings: The system saves 700,000 USD annually in operating costs.

- Carbon Reduction: Lowers CO₂ emissions by 4,272 metric tons per year, equivalent to planting 70,488 trees over 10 years.

- Water Savings: By discharging treated wastewater into Mill Creek, the plant avoids excessive water consumption and conserves natural resources.

Why CCHP Matters for Wastewater Treatment Plants

Wastewater treatment plants (WWTPs) face rising energy costs and environmental challenges. By adopting CCHP systems with BROAD absorption chillers, WWTPs can:

- Produce power at a cost below retail electricity.

- Replace purchased fuels for heating needs.

- Qualify as a renewable fuel source under green energy programs.

- Enhance operational reliability.

- Reduce emissions of greenhouse gases and pollutants.

- Support utility peak load shedding for grid stability.

Fun Facts about WWTP CCHP

- In the U.S., a typical WWTP processes 100 gallons of wastewater daily per person.

- Each million gallons per day (MGD) of wastewater can produce enough biogas to generate 30 kW of electricityand 2.4 MMBtu/day of thermal energy in a CCHP system.

- The cost of generating electricity with CCHP ranges from 1.1 to 8.3¢ per kWh, compared to market prices as high as 21¢ per kWh.

BROAD Indonesia: Delivering Smarter Energy Solutions

This project at CVWRF is a global reference case showing how BROAD’s clean technology transforms wastewater into a sustainable energy source. For Indonesia, where urban growth and industrial development are increasing the demand for wastewater treatment and energy efficiency, BROAD CCHP solutions provide a reliable and eco-friendly path forward.

By integrating biogas-fueled power generation with BROAD absorption chillers, Indonesian wastewater plants, factories, and commercial facilities can:

- Cut energy costs,

- Improve sustainability performance, and

- Contribute to national emission reduction targets.

🌱 BROAD Indonesia is ready to support utilities, municipalities, and industries with proven CCHP and absorption chiller solutions.

Turn waste into clean energy. Build a greener future with BROAD.