Sustainable Cooling Solutions in Textile Manufacturing

PT Indorama Synthetics Tbk, established in 1975, is a leading Indonesian company with manufacturing facilities in West Java. Initially specializing in cotton spinning, the company has since expanded its operations to produce Polyester Filament Yarns, Polyester Staple Fibers, PET Resin, Polyester Chips, and Polyester Filament Fabrics for global markets. To enhance energy efficiency and reduce environmental impact, the company has integrated BROAD Steam Chiller technology into its manufacturing process.

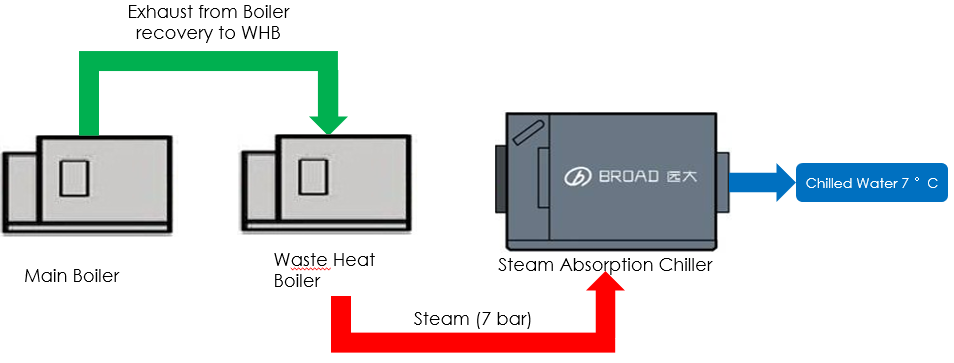

Innovative Use of Steam Chillers for Industrial Cooling

By utilizing BROAD Steam Chillers, PT Indorama Synthetics Tbk effectively repurposes waste steam for cooling applications within its facilities. This innovative approach optimizes energy consumption while reducing reliance on conventional electricity-powered cooling systems, leading to substantial operational cost savings and environmental benefits.

Significant Carbon Reduction and Energy Savings

The adoption of BROAD Steam Chiller technology has resulted in remarkable energy savings and carbon emission reductions:

- Annual Operating Time: 8,760 hours

- Annual CO2 Emission Reduction: 7,840 tons

- Equivalent to Tree Planting: 428,392 trees

Advantages of BROAD Steam Chiller Technology

The implementation of steam chiller technology offers multiple benefits for industrial facilities, including:

- Optimized Energy Utilization: Converting waste steam into useful cooling energy.

- Reduced Carbon Footprint: Lowering greenhouse gas emissions by minimizing reliance on fossil fuels.

- Enhanced Sustainability: Supporting global environmental initiatives while maintaining high operational efficiency.

Conclusion: A Model for Sustainable Industrial Cooling

PT Indorama Synthetics Tbk’s adoption of BROAD Steam Chillers demonstrates a successful strategy for improving energy efficiency in textile manufacturing. By leveraging waste steam for cooling, the company not only reduces operational costs but also significantly contributes to environmental sustainability.

For industries aiming to optimize energy usage and reduce emissions, BROAD’s steam chiller technology provides a proven solution for achieving sustainable and efficient manufacturing processes.