The “Driving Industrial Sustainability Through Absorption Cooling Innovation” webinar, hosted by BROAD Indonesia on November 28, 2025, successfully introduced industrial professionals to the significant benefits of absorption cooling technology. The event highlighted how these systems contribute to sustainability by reducing electrical energy consumption and utilizing waste heat sources.

Key Discussion Points and Technical Insights

The webinar, featuring speakers Aldo Susanto (Customer Manager, BROAD Indonesia) and Luna Zhao (Regional Manager, BROAD AC International), covered several critical topics:

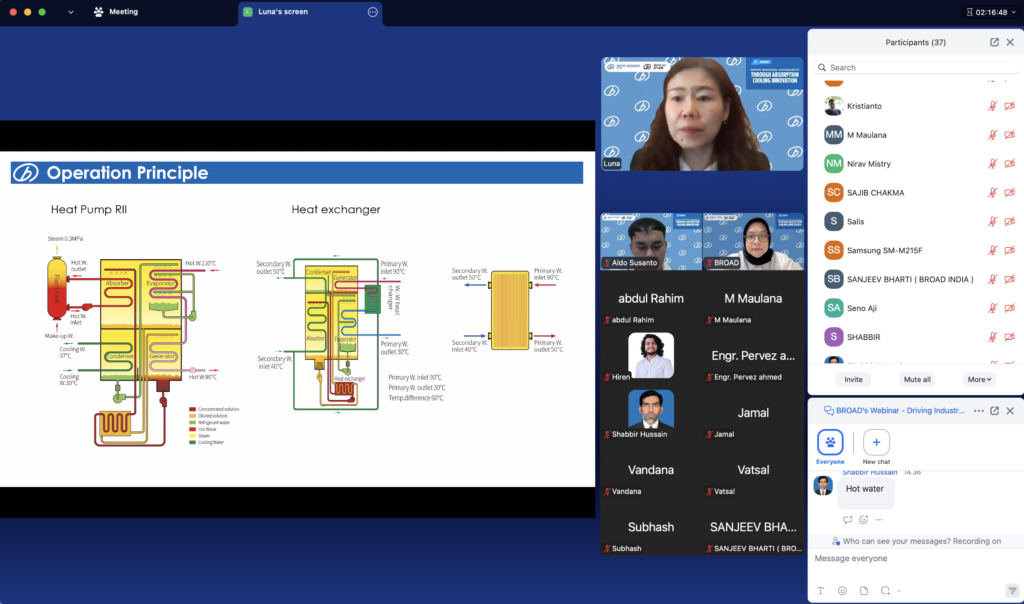

- Absorption Chiller Fundamentals: An overview of operating principles and a comparison of absorption chillers versus electric chillers.

- Waste Heat Utilization: The benefits of using waste heat and exhaust-fired applications to improve system efficiency and support environmentally responsible operations.

- Operational Reliability and Maintenance: Guidelines for maintenance, operational reliability, crystallization prevention, and best practices.

- System Design: Considerations for both gas-fired and exhaust-fired units, including industrial case applications.

Participants engaged actively in discussions on energy losses, waste heat potential, and challenges in implementing energy-efficient systems.

Participant Engagement and Technical Q&A

The session generated strong engagement, with participants praising the webinar as “informative,” “professional,” and “technically useful”.

The Q&A segment was rich with practical, technical queries, demonstrating the audience’s deep interest in the technology:

- Crystallization Prevention: Questions included how to prevent crystallization and whether animation or technical notes could be provided.

- System Components: A participant asked why BROAD selects titanium tubes over copper, despite copper’s higher thermal conductivity.

- Exhaust System Design: Queries arose concerning the cleaning interval for dirty exhaust areas and the potential for an online cleaning system to avoid frequent shutdowns due to heat transfer generator (HTG) choking.

- Performance Metrics: Other questions focused on chiller leaving steam temperature, pressure, and enthalpy values, as well as gas design pressure requirements.

Future Focus: Deepening Technical Content and Collaboration

Based on participant feedback, the review for the next webinar emphasized deepening technical content and strengthening international collaboration. Key areas for improvement include:

- Content Deepening: Adding more troubleshooting, maintenance topics, and a breakdown of Return on Investment (ROI) and payback analysis.

- Specific Technical Details: Focus on crystallization handling procedures, gas pressure design parameters, and vacuum monitoring.

- Global Outreach: Formalizing cooperation with overseas branches to increase active promotion, widen international outreach, and collect international market feedback.

Overall, the webinar successfully strengthened BROAD’s global positioning as a leader in sustainable cooling solutions and highlighted the importance of inter-branch collaboration.