Sustainable Cooling and Heating Solutions for High-End Steel Production

Linyi Iron and Steel Investment Group, located in the Advanced Special Steel Park in Lingang District, spans 215 hectares and specializes in producing high-end special steel, including oil billets, bearing steel, and gear steel. To optimize energy utilization and enhance sustainability, the company has integrated BROAD BDH400 absorption chillers into its operations.

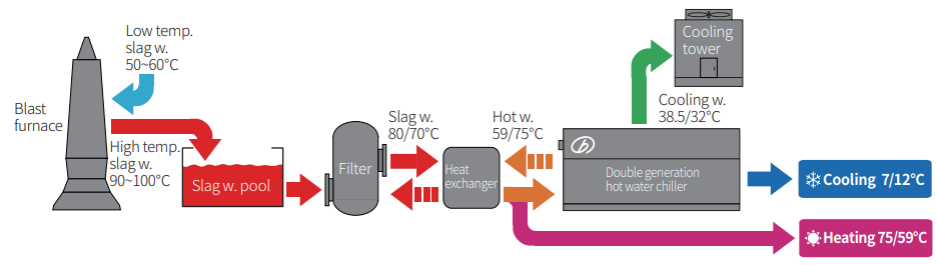

Innovative Use of Waste Heat for Cooling and Heating

The facility includes a 2,770m³ blast furnace and two slag water heat exchange stations, where 75°C hot water from slag flushing is repurposed to power two BROAD BDH400 absorption chillers (2,605 kW per unit). This system efficiently provides cooling for office areas, dormitories, and control rooms while also supplying heating during winter, reducing overall energy consumption and environmental impact.

Significant Carbon Reduction and Energy Savings

The adoption of BROAD absorption chillers has resulted in substantial energy savings and carbon emission reductions:

- Annual Standard Coal Savings: 5,000 tons

- Annual CO2 Emission Reduction: 12,800 tons

- Equivalent to Tree Planting: 700,000 trees

Benefits of BROAD Absorption Chiller Technology

By utilizing waste heat for cooling and heating, BROAD absorption chillers offer multiple advantages to industrial facilities, including:

- Increased Energy Efficiency: Maximizing the use of residual heat from industrial processes.

- Lower Carbon Footprint: Reducing reliance on fossil fuels and decreasing emissions.

- Enhanced Sustainability: Supporting eco-friendly initiatives and reducing environmental impact.

Conclusion: A Model for Sustainable Industrial Operations

The integration of BROAD absorption chillers at Linyi Iron and Steel Investment Group showcases a successful implementation of energy-efficient solutions in the steel industry. By leveraging waste heat for both cooling and heating, the company not only lowers operational costs but also contributes to a more sustainable and environmentally responsible industrial sector.

Industries looking to optimize energy use and reduce emissions can benefit from BROAD’s advanced absorption chiller technology, paving the way for a greener and more efficient future in manufacturing.