In the world of premium chocolate production, temperature isn’t just a setting—it’s the secret to quality. For a global leader like Barry Callebaut (PT Papandayan Cocoa Industries), maintaining the perfect climate at their Bandung facility is critical to transforming Indonesian cocoa beans into world-class cocoa butter and powder.

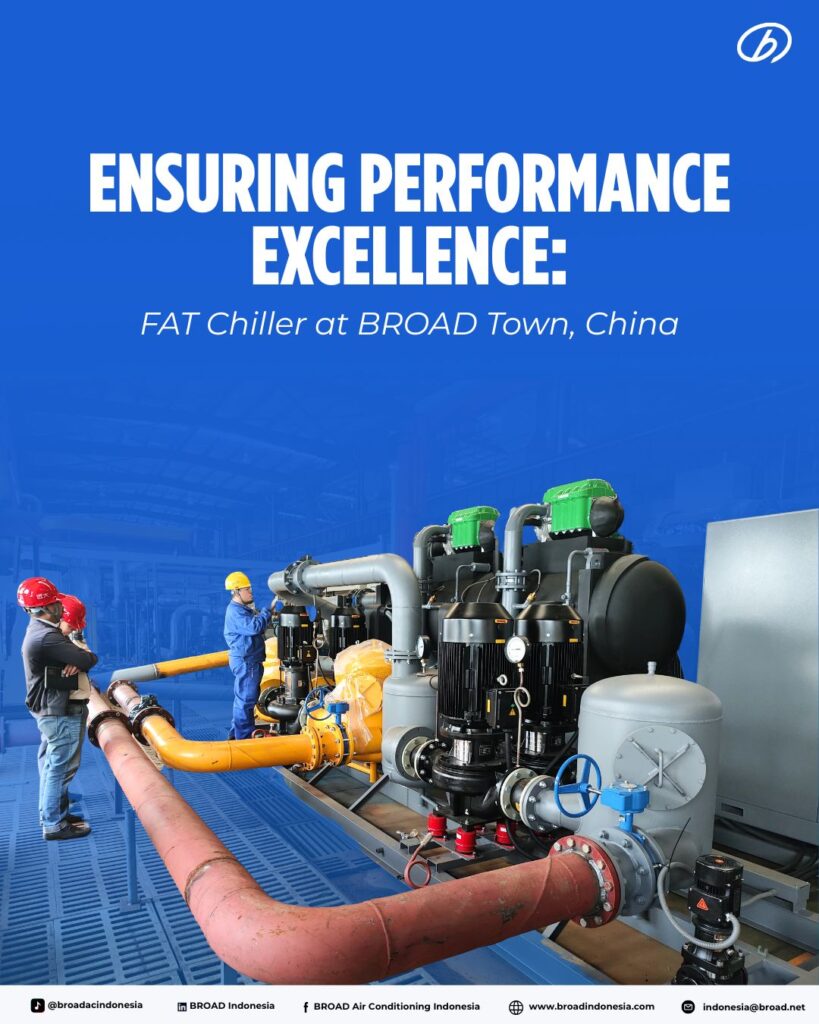

Recently, BROAD Indonesia took this commitment to quality a step further by hosting a comprehensive Factory Acceptance Test (FAT) at BROAD Town, China. This milestone marks a significant chapter in the partnership between BROAD and PT Papandayan Cocoa Industries, ensuring that the next generation of cooling technology is ready to perform from day one.

What is a Factory Acceptance Test (FAT)?

A Factory Acceptance Test is a rigorous quality control process where industrial equipment is tested under real-world operating conditions at the manufacturer’s facility before shipment.

For Barry Callebaut, the FAT provided a transparent, data-driven look at how BROAD’s absorption chillers handle high-demand industrial loads. By simulating the specific humidity and temperature requirements of the Bandung factory, we ensured that every technical specification—from energy consumption to cooling capacity—was met with 100% accuracy.

Why the FAT Matters for PT Papandayan Cocoa Industries:

- Operational Reliability: Identifying and fine-tuning performance parameters at the factory eliminates downtime risks during on-site installation.

- Energy Efficiency Verification: Barry Callebaut is a champion of sustainability. The FAT allowed their team to witness firsthand the low-carbon footprint and high efficiency of BROAD’s Power Efficiency Chiller technology.

- Hands-on Training: The session served as a collaborative knowledge exchange, allowing the PT Papandayan team to interact with the engineers who built their units.

Sustainable Cooling for the Cocoa Industry

The cocoa processing industry requires steady, reliable cooling to manage the heat generated during roasting and milling. Traditional electric chillers often lead to skyrocketing utility bills and high carbon emissions.

By choosing BROAD’s Absorption Chillers, PT Papandayan Cocoa Industries is leveraging advanced technology that can utilize waste heat or natural gas, significantly reducing electricity dependency. This alignment with “Green Manufacturing” not only protects the environment but also provides a long-term competitive advantage in the global market.

“At BROAD, we don’t just sell chillers; we build partnerships based on trust and technical transparency. Hosting the PT Papandayan Cocoa Industries team at BROAD Town allowed us to prove that our ‘Made for Quality’ promise is backed by rigorous data.” — BROAD Indonesia Team

The Road Ahead: Strengthening Indonesia’s Industry

As PT Papandayan Cocoa Industries continues to grow its footprint as a premier exporter of Indonesian cocoa, BROAD Indonesia remains dedicated to supporting that growth with reliable, energy-efficient HVAC solutions.

The successful completion of this FAT is more than just a box checked—it’s a guarantee that when the cooling system starts at the Bandung plant, it will deliver the precision and reliability that the Barry Callebaut brand demands.

Ready to Optimize Your Industrial Cooling?

If you are looking for energy-efficient, reliable HVAC solutions that can stand up to the most demanding industrial environments, let’s talk.